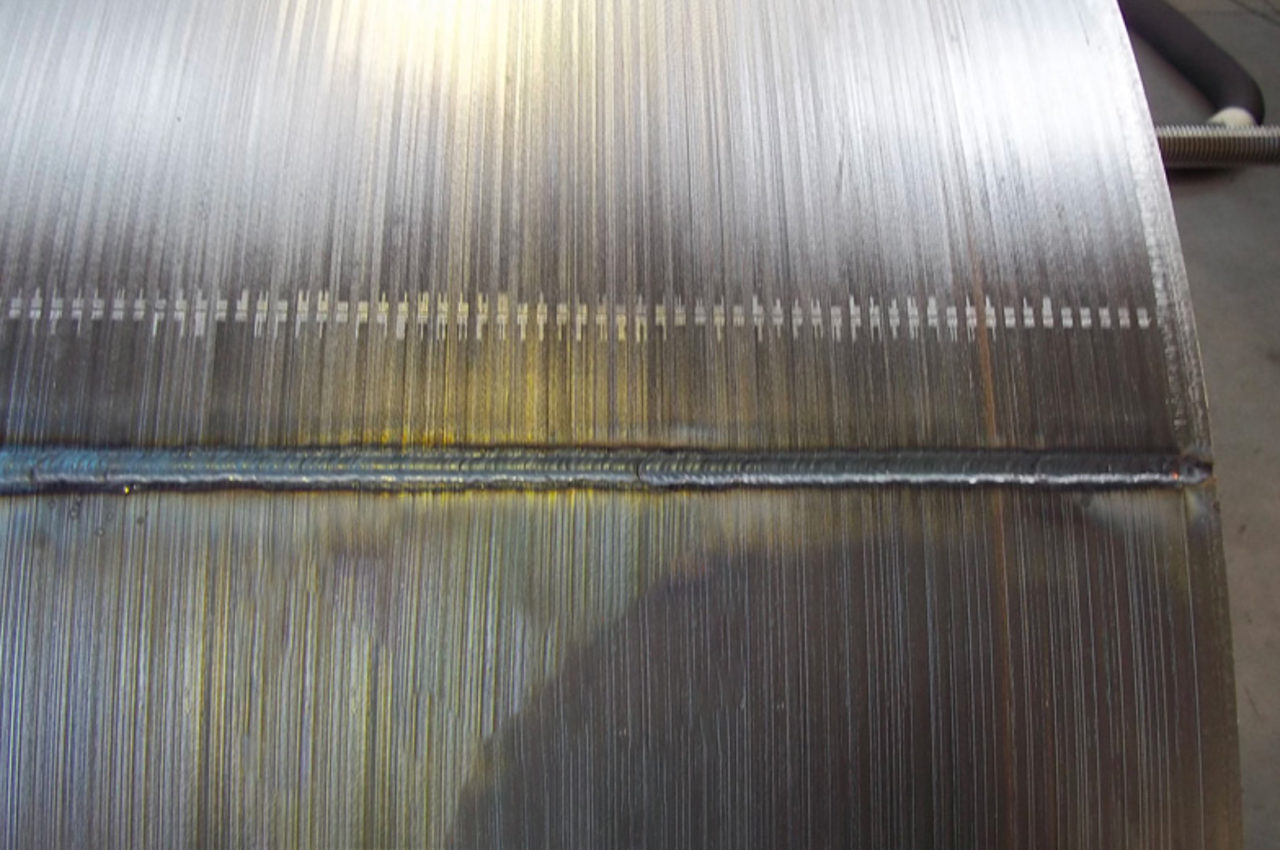

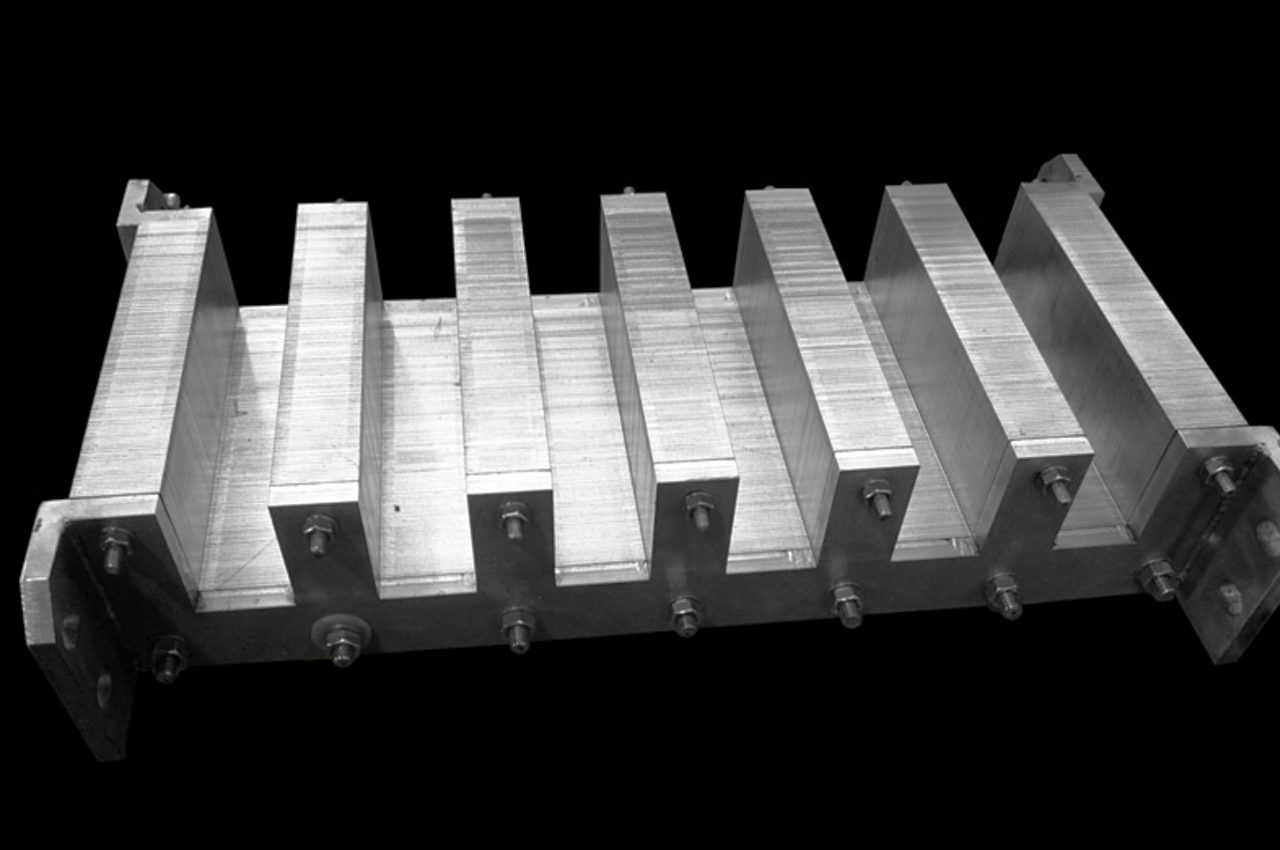

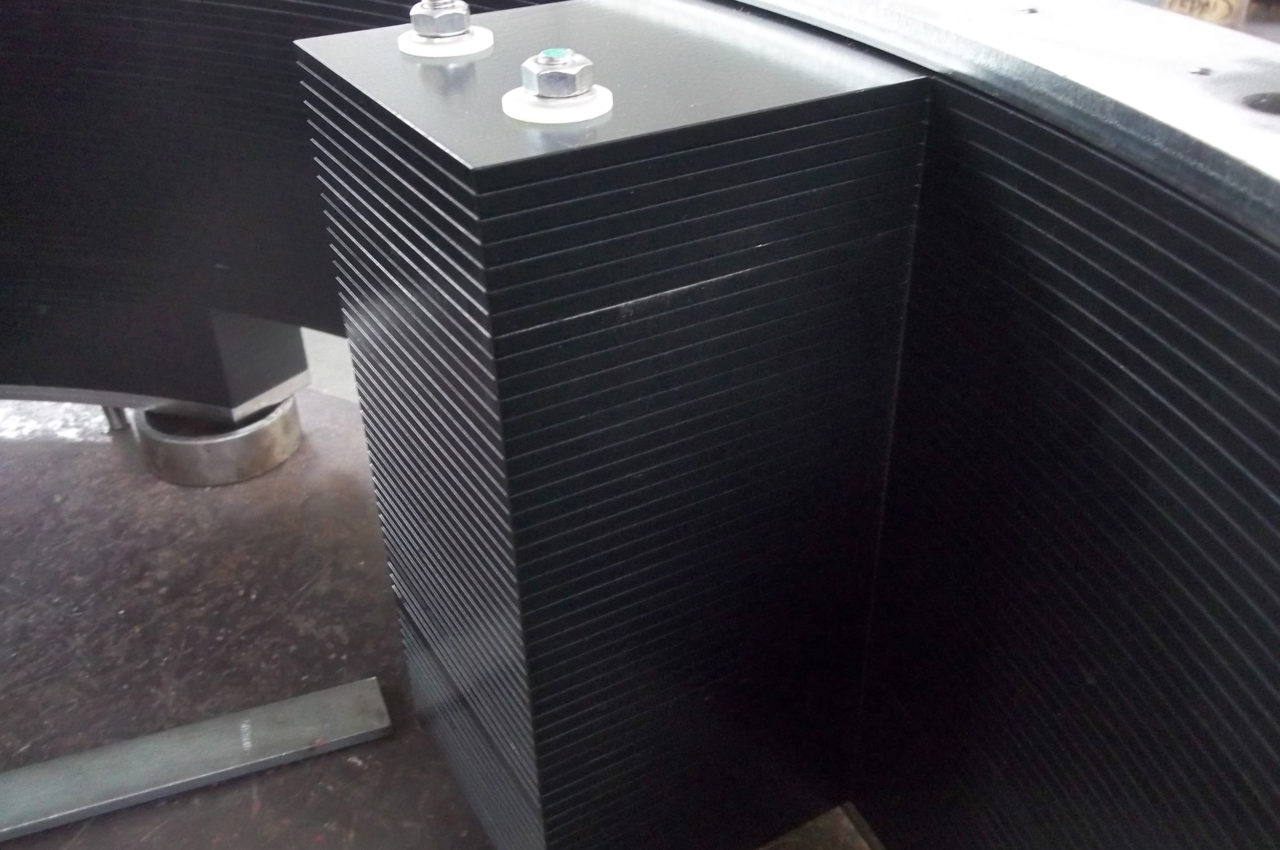

Stacks of different sizes, with straight or curved profile, either welded or bonded, complete with drilling and grinding of back side.

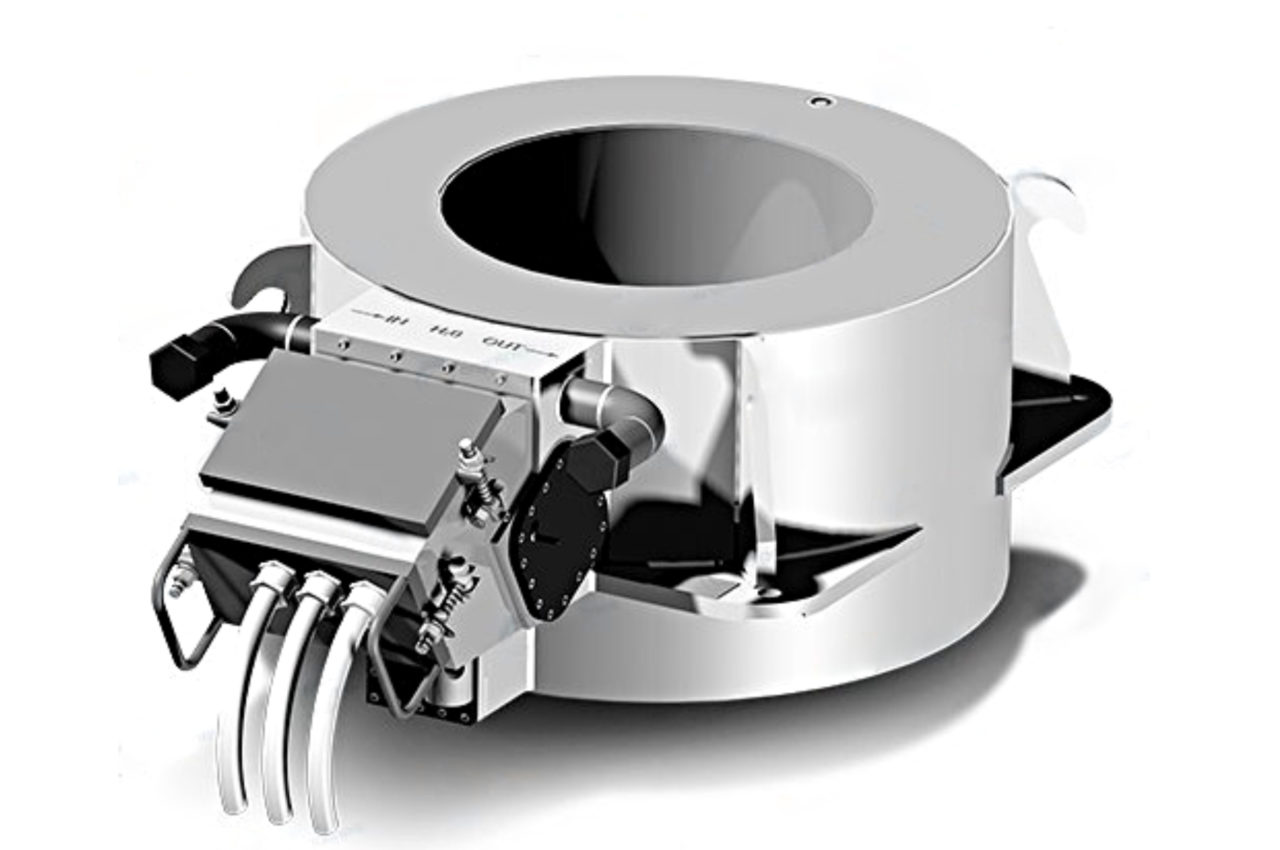

Cores for several applications, such as stirrers or transformers, complete with pressing plates, tie rods, machining or surface treatments upon request.

LOW POWER FOR HIGH PRECISIONS

Cutting-edge technology

Our laser machines are equipped with a fiber source customized to our specifications, with a very small diameter laser beam. Such a thin laser beam allows the manufacturing of very complex details with extreme accuracy and precision. Furthermore, the power is so low that it minimizes heat immission to the metal during the cutting process.

Go to the next product

Laminations laser cut

Go to the next product

Laminations laser cut

Let's get in touch

Discover how we can contribute to your performancecontatti

Contact us

Amwerk founder and owner

Travis Kirkpatrick

As a family owned and operated company we are hands on business owners and intimately involved in daily operations. Time on the shop floor interacting with employees is routine, promoting their development and be proud of their work.

Travis Kirkpatrick, Owner